Pottery Blog - Making Handmade Mugs & Tableware — Glaze Recipes and Techniques

Developing A Rustic White Pottery Glaze

How hard can it be? Surely white glazes must be the easiest of all to get right... If you're just after glaze recipes you can sign up to my mailing list via the link near the bottom of the page. Reading this article may help you develop your own though if you'd like to do that. What makes a glaze white? Most white glazes are simply a base glaze with some kind of opacifier added. The base recipe could vary a lot depending on your firing temperature and atmosphere of the kiln. There's lots of info on the internet about base glaze recipes...

A Beginners Guide To Making Your Own Pottery Glaze - Step by Step

I imagine you found this article because you're already producing pottery and are interested in making your own pottery glazes. You're in the right place!

There are many books on glaze making which cover this topic in much more depth. To be honest I haven't read many of them - and I do like reading books.

Stoneware Single Firing Schedule and Results

This is a follow up to my article on raw glazing single firing experiments. Single firing results Whilst loading the kiln I had a problem with glaze flaking off, especially around the rims. I had to rebrush glaze onto most of the pots. The clay content of both glazes is quite high which I believe is the problem. I’ve included my notes on the firing. I think the firing schedule itself was ok, I had no breakages, and can’t see any pinholing or bloating which are associated with firing too fast. I did have a major problem with glaze crawling....

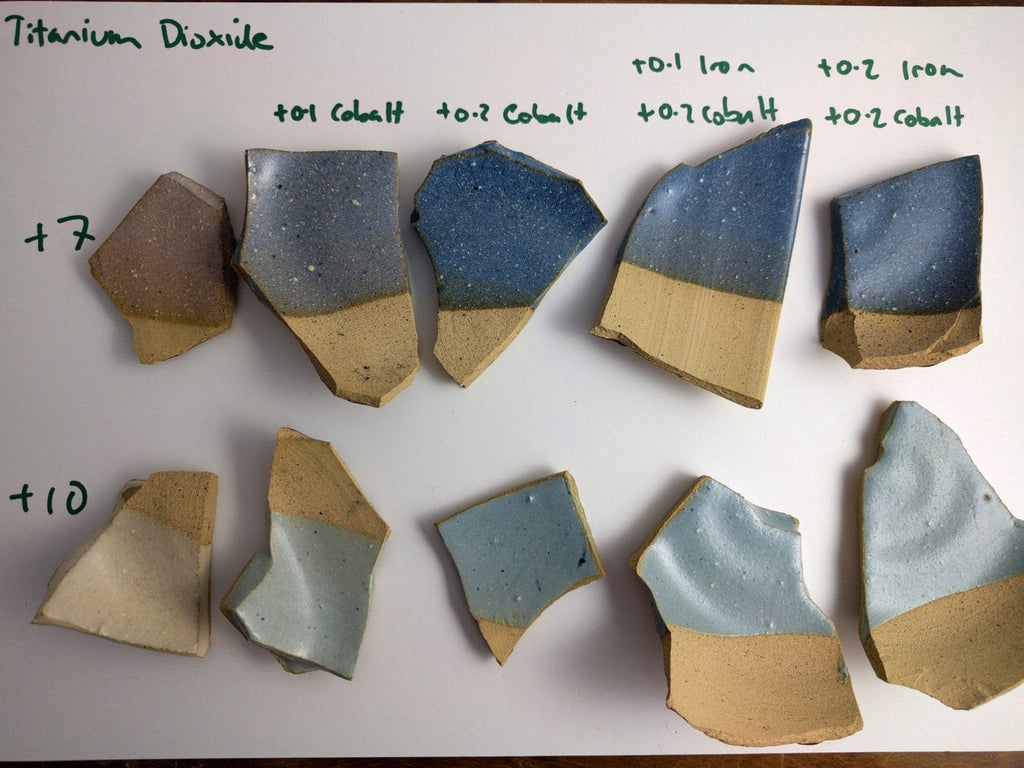

Comparison of glaze opacifiers and developing dusty blue glaze

I’ve been doing some glaze testing to try and create a glaze I can see in my head. It’s a light blue grey matt glaze with darker speckles. I thought I would investigate the difference glaze opacifiers have at the same time. The starting point is the base glazes I have been developing recently. Having tested various clays available, I wasn’t happy with the porosity of them when fired to cone 6, so I’ve recently started firing to cone 8. I use software at glaze simulator.com to develop glazes and also insight live which can be accessed by group membership...

Raw Glazing and Single Firing Experiment

I’ve decided to try and eliminate bisque firing by raw glazing pottery. Most potters nowadays do a bisque firing, which partially bakes the pottery so it can no longer return to mud. This makes glazing easier, before a second glaze firing takes place. I’ve read about single firing before and it seems fraught with difficulty. It involves applying a water based glaze to semi or fully dried clay which will immediately want to dissolve. Furthermore, the coating of glaze inhibits the release of water and impurities from the clay during firing which increases the likelihood of explosions and kiln damage....

Avoiding Pesky Pin Holes and Glaze Dimples with Proper Carbon Burnout

I had a very unhappy kiln opening a few weeks ago with glaze dimples and pin holes all over my bigger pieces. I’ve had the problem on a smaller scale before, but nothing to this extent. It’s quite soul destroying finding a load of work that needs to be binned. I sulked for a couple of days, then with gritty determination I vowed to find a solution! Glaze pin holes and dimples – how to solve it? Initially, as a glaze defect I began pointing fingers at the glaze. The pieces in question have been glazed in two different layered...